OneCNCXR6 40.38

OneCNC has today released OneCNCXR6 Version 40.38 for all OneCNCXR6 Products.

This is now available in the OneCNC Update Server

The major items of this update are:

Languages

Updates to all the language translation.

OneCNCXR6 now includes the Chinese Traditional Language

Fixes or changes

The Profile creation function in OneCNCXR6 Lathe has been updated.

Japanese version of DNC link has had font correction.

New Help File

New Help file which includes the latest additions as well as many other updated features and examples to bring it to now fully OneCNCXR6.

New Shortest Path Feature in Milling Versions

This feature is used for positional machining where the machine control does not have the ability to go the shortest path when when performing a rapid movement from one position to another in positional machining.

This is especially for the Haas control as well as other controls that do not have the automatic shortest path functionality..

If for example we were drilling a hole at 55 degrees around A Axis then the next move was to drill a hole at 5 degrees around A Axis the machine could rapid all the way around from 55 degrees to 5 degrees.

This new "shortest path"setting when active will assist the machine by posting code for the shortest path which is only 10 degrees of movement instead of 50 degrees.

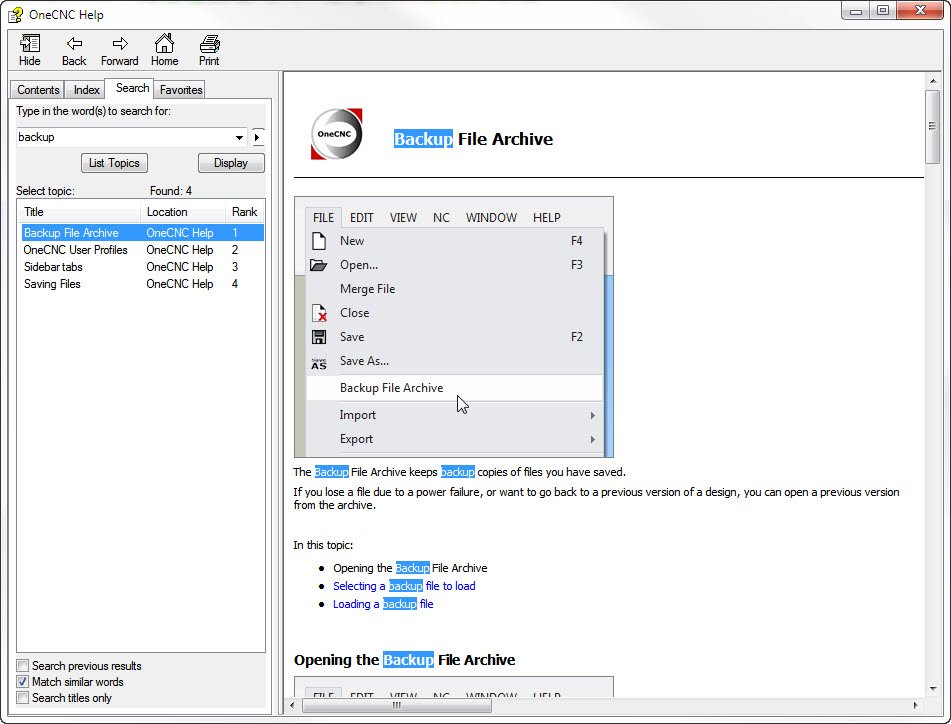

New Backup Archive System.

This new feature control can be found here in the help file here:

This is not designed to replace the present method saving and backing up of your files that you may be presently using however this is a system that may assist those that do not have a system of saving files.

This enables to have at least one backup of each file per day which is shown as white rather than the greyed files which are recent of the day for the file. There is a max of 100 of the recent so as the recent fill up the greyed out oldest files will be cleared.

If the user is working on one file over several days there will be at least always one backup for each day and as I say there may be more greyed out ones as if they are within the total of the 100 recent files.

If a user does not want to make backups or use the archive system it can be turned off in properties.

The old system of auto save is still there and is a separate function from the new backup archive system.

5 Axis Simultaneous Machining New Functionality

The 5 Axis simultaneous function has had a major upgrade.

There are changes in:

(a) The Post

(b) The Tool Dialog

(c) The Angle Control Functionality

(d) New Multi Axis Simulation speed

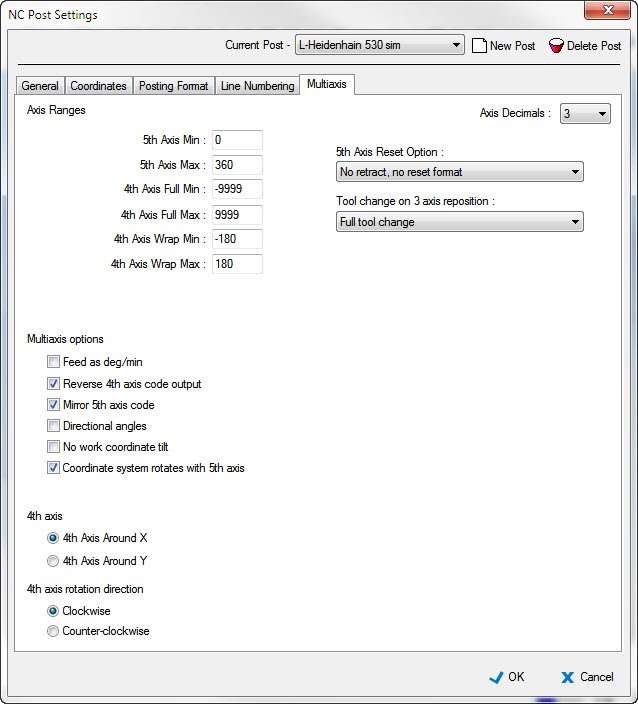

(a) The Post Changes

Here are changes in the post:

There is a new setting drop down in the Multiaxis tab of the post

The new 5 axis reset option has 3 settings available

(a) No retract and No reset format

(b) Retract and Insert reset format

(c) Insert reset format only

In the case of Heidenhain 530i control to obtain full continuous machining without the necessity to reset the machine we have created new logic to give continuous machining without the necessity to reset the machine control without any limit to the rotations.

This has been tested on a Hermle with a Heidenhain 530i for continuous operation and makes it much easier for the operator because the operator then knows where the position of the machine is at all times because the control only shows the 5 axis 0-360 deg of the C axis.

This is a much safer setting if the control has the available logic or control to always take the shortest route.

You will notice the top setting 5 axis min and 5 axis max I have set to min 0 and max 360 for a Heidenhain 530 post.

This is new functionality in conjunction with the setting on the right called 5 axis reset option.

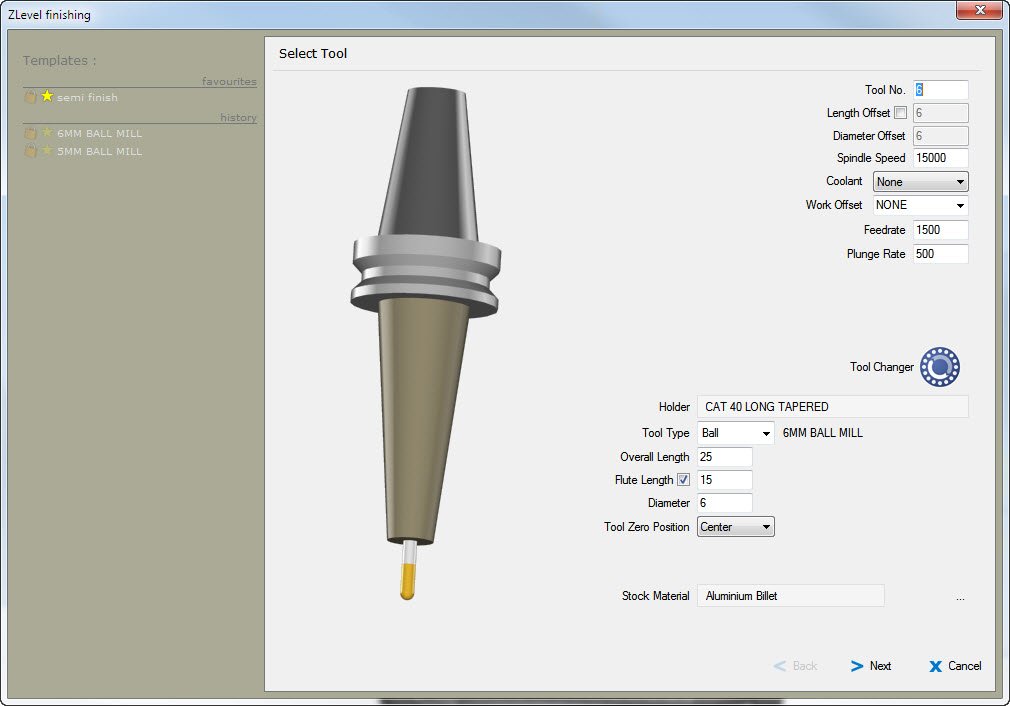

(b) The Tool Dialog Changes

There is now ability to set tool centre point of the ball cutter in 5 axis simultaneous as well as the previous setting of tip setting.

This setting is only seen in OneCNC Mill Expert with 5 axis simultaneous function

This offset settings choice only applies to 5 axis simultaneous.

The tool dialog for 5 axis simultaneous has a new setting for creating the tool set position at the tool ball centre rather than the tip.

This can have a dramatic improvement in viewing the tool path preview as well as the tool path back plot.

This setting of course changes the offset setting in the machine control for the user.

To assist we have added it to the job sheet to remind the user although it is a safe setting because if the user does not set it at the machine the tool would be short and not gouge.

We have been doing extensive research and development here on 5 axis and believe that this setting helps the user to see the tool path in the preview as well as the backplot

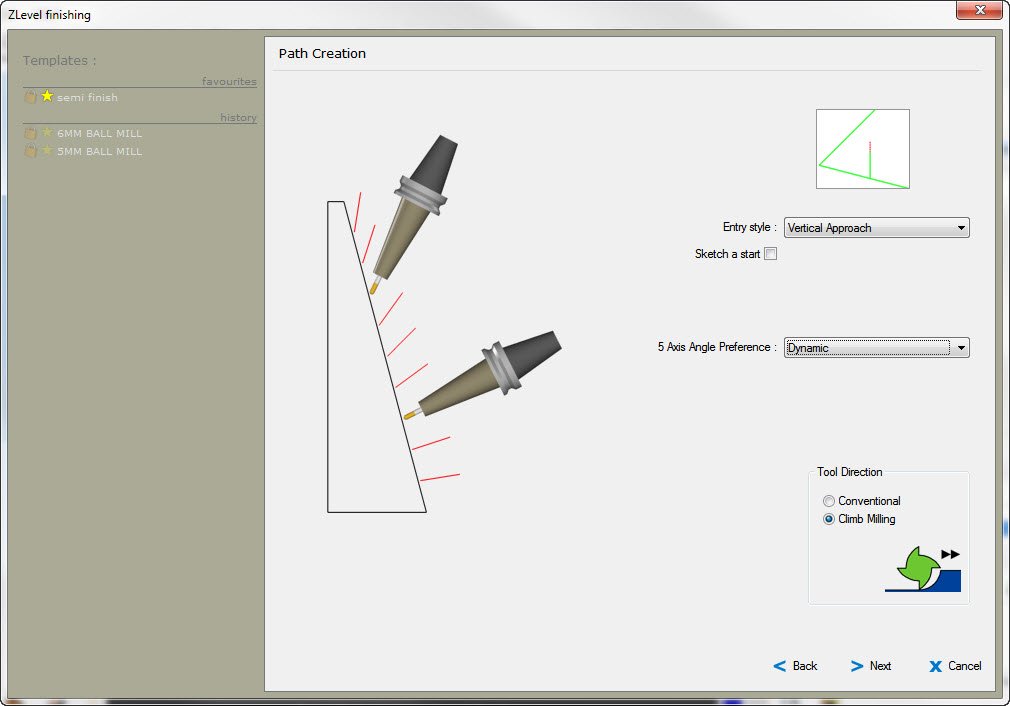

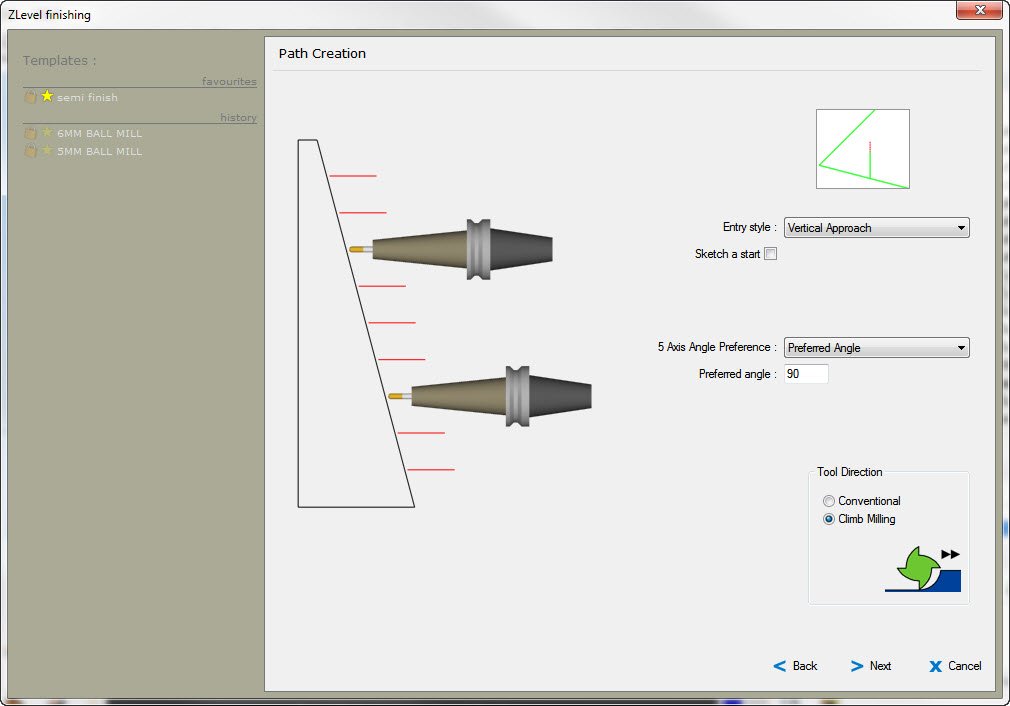

(c) New the Angular Control Settings

When using the 5 axis simultaneous function the angular control dialog will appear in the wizard settings.

This will not show in your existing drawings but will show if re-programmed with this new feature.

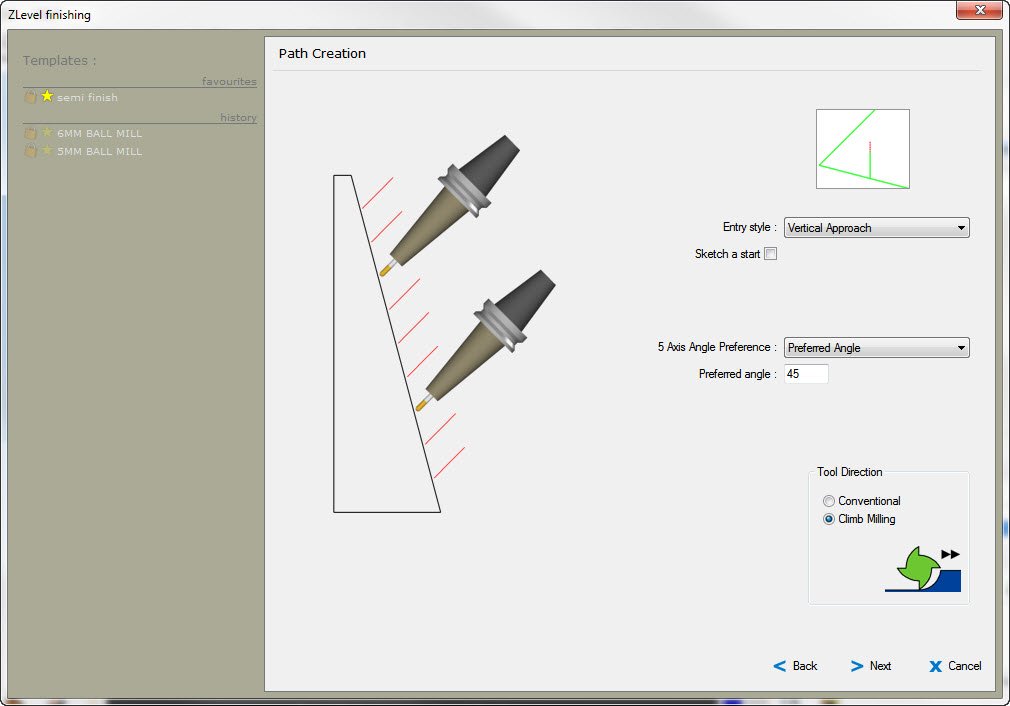

The next change to the 5 axis simultaneous is in the angular control ability.

Here is another pic of the same dialog with a different preferred angle setting

As the angle is changed or set the tool and holder will dynamically update and show the set angle.

This new angular control we have found in development and testing to be very good for smoother machine operation and even smoother simulation in OneCNC.

There is no change with the Entry Style at this point which it the top setting in this dialog but the new 5 axis Preferance Angle is a new development. This still has the same auto tilt ability as previous with a setting but gives new control ability as well.

There are 3 settings in 5 axis Angle Preference

(a) Dynamic

The dynamc setting is how OneCNC 5 axis prior to this version 40.31 worked. This just works by collision control making sure the tool, holder and head clears.

(b) Preferred Angle

The preferred angle setting obeys the angle set unless it encounters an area where this preferred angle is not suitable.

As you change this angle it will dynamically show the holder and the angle selected in the dialog to assist users to use the correct angle.

As an example if you were machining a vertical standing cylinder shape in the 5 axis using 5 axis Z level finishing using a preferred angle of say 45 degrees it would stay at a constant angle of 45 degrees for the whole operation.

This makes for very smooth machine control and excellent finish.

This also improves the OneCNC simulation smoothness too due to less angle flipping.

(c) Auto Angle

This setting creates the program function where the angle is set to an automatic angle that it derives from the processing of the requested settings.

OneCNC then uses this angle for the process and a quick look in the preview will show you what it has set.

(d) New Multi Axis Simulation Speed

The simulation of multi axis simulation you will notice simulation of multi axis is now much faster.

To get the best from this Multi core PC with Windows 7 64 Bit or later we have further optimised the simulation to use where possible multi threading and multi core to assist with the simulation speed.

You may also notice with the new 5 axis simulation tool angle control when this is used as a preferred angle that it can make a much smoother machine movement and also a much smoother simulation that also assists with simulation speed.

OneCNC Updates

OneCNCXP 5.23

Jul 31 2003

OneCNCXP 5.27

Sep 05 2003

OneCNCXP 5.29

Sep 12 2003