OneCNC Deutschland at METAV 2016

OneCNC Deutschland exhibited at METAV in Dusseldorf Germany 23-27 Feb 2016

METAV in Düsseldorf has been the venue where technology providers can present to the trade world their metalworking, automation, production instrumentation, and software innovations to industry.

This presentation of current developments becomes the stage for future investments. METAV provides a platform for metalworking subjects aligned to users, for the automotive and vehicle industries, machine and plant building, aerospace, medical engineering, power and environmental technologies, precision mechanics, optics, electrical and electronic engineering, to mention but a few. METAV 2016 reached a wide range of customers.

OneCNC Deutschland welcomed the opportunity to meet personally with so many existing customers due to being very popular CAD/CAM in Germany.The show was very well attended by existing customers as well as many potential customers.

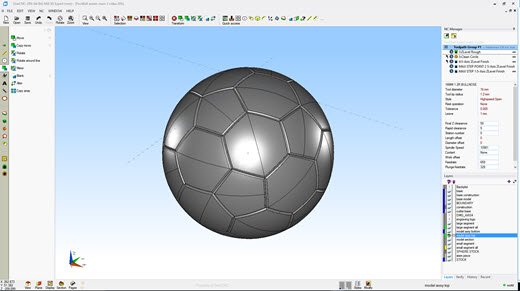

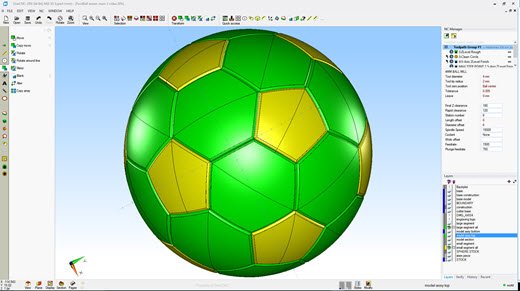

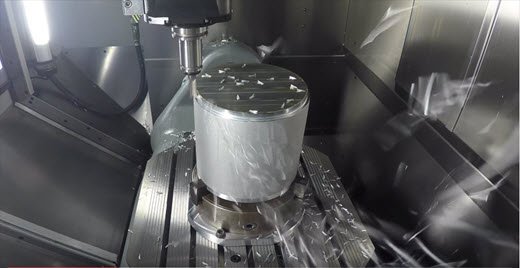

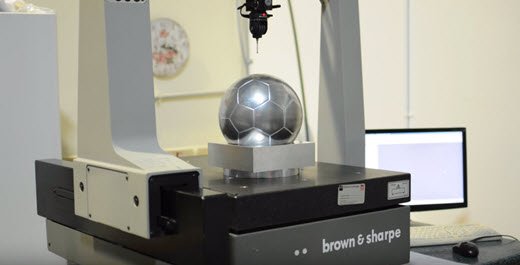

OneCNC was very busy throughout t the whole show demonstrating the unique advantages of the products to a large selection of manufacturers.. At times the halls were quite crowded with visitors to this popular exhibition so muc so it was difficult to find time to take a picture of the OneCNC stand..

OneCNC Deutschland with 3 application engineers on hand were kept very busy during the exhibition. If you were unable to have a personal demonstration of the OneCNC products please contact OneCNC Deutschland.

OneCNC Deutschland offers on-site training as well as on-line training and full support for all customers in Germany. If you did not have time to visit the fair and would like to evaluate the OneCNC product contact OneCNC Deutschland.

OneCNC Deutschland

Hornscher Weg 126

32657 Lemgo

Germany

ph:+ 49(0) 5261-288940

email:

web: www.onecnc.de

OneCNC Updates

OneCNC XR9 Release 74.53

Nov 23 2023

OneCNC XR9 Release 74.44

Sep 25 2023

OneCNC XR9 Release 74.30

Jul 06 2023