OneCNC UK promotes "Manufacturing Efficiency"

OneCNC UK participated in "Manufacturing Efficiency" demonstrations at the invitation of Haas Automation Thursday 23rd April 2009 at the Hethel Engineering Centre.

Hethel Engineering Centre, is located at Chapman Way, Hethel, Norwich, NR14 8FB UK. Hethel Engineering Centre is a business dedicated to supporting the growth and success of high performance engineering and manufacturing companies and individuals throughout the region.

This is an amazing venue and a perfect opportunity for OneCNC UK to showcase OneCNCXR3 and in particular the High Speed machining real-time on a Haas machine to invited guests.

The theme of the day was a focus on increasing your productivity with live cutting demonstrations on the latest American CNC Technology.

Here we can see OneCNC UK Technical Director Peter Gillespie (third from right) demonstrating the functionality of OneCNCXR3 and on the left is a Haas VMC machining a part programmed earlier.

Peter (right) is always in popular demand at these information and demonstration days due to his vast machining and programming knowledge.

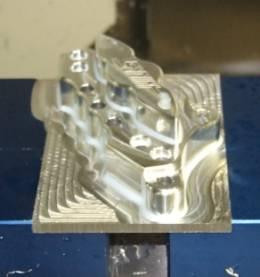

Here is one of the components machined and demonstrated on the day.

If you would like to find how you can benefit from the OneCNCXR3 manufacturing efficiency contact the OneCNC office for your area. You will be amazed at how inexpensive OneCNC is and how much you can gain in efficiency.

OneCNC Updates

OneCNC XR9 Release 74.53

Nov 23 2023

OneCNC XR9 Release 74.44

Sep 25 2023

OneCNC XR9 Release 74.30

Jul 06 2023