Case Study of Kyocera's CAD/CAM Implementation: The Attractiveness of OneCNC's Efficiency and Cost Reduction

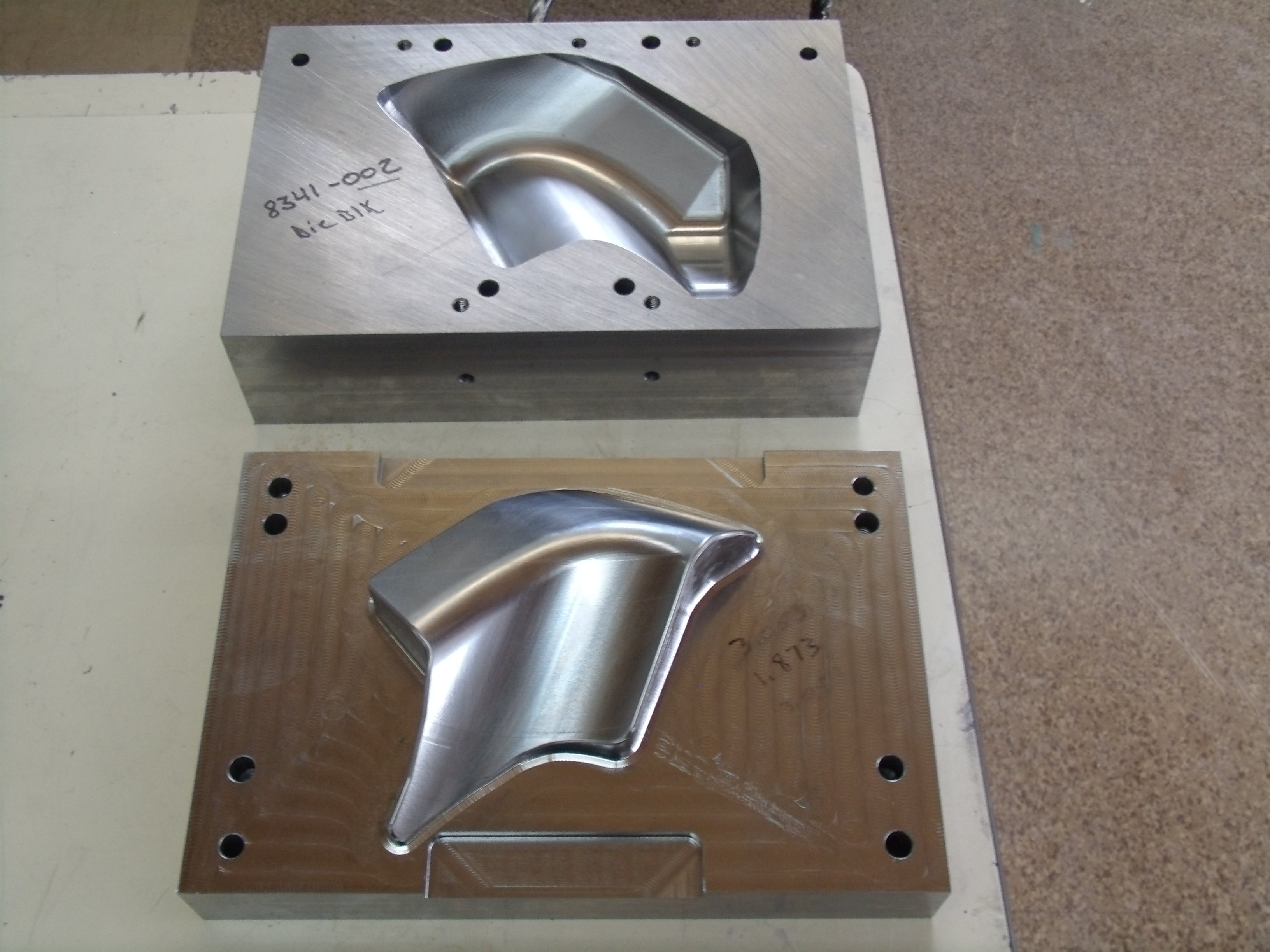

Kyocera Corporation is one of Japan's leading manufacturers of electronic components and electrical equipment, and its Shiga Yohkaichi Plant manufactures a wide variety of products, including fine ceramic components, machine tools, electronic components, and printing devices.

The company has introduced OneCNC many times in multiple departments in the same factory.

About the introduction and launch of OneCNC

Mr. Yokoyama joined the company in 2005 and was assigned to another division. After that, in 2011, he was assigned to the Mechanical Parts Manufacturing Section 2, and has been working as an NC programmer since 2013.

Initially, the department to which Mr. Yokoyama was assigned had three CAD/CAM systems, including OneCNC, but his predecessor's boss decided to introduce OneCNC, and after that Mr. Yokoyama himself started using OneCNC. I decided to do it.

At that time, Mr. Yokoyama was only in his second year of transfer, but he says that he was able to learn in a short time thanks to the easy-to-understand interface and excellent operability even for beginners.

Currently, no one in the same department uses other CAD/CAM, and it is unified to OneCNC.

Regarding the introduction of multiple OneCNC units in each department

Five OneCNC units have been installed in four departments within the Yokkaichi Plant of Kyocera Corporation.

When asked why OneCNC is currently being used in many departments in the factory, he said:

“At our company, a system called Amoeba Management*, which evaluates profits on a department-by-department basis, is pervasive. The decision criteria for introducing CAD/CAM is the same as processing machines, whether it will generate profits for the department.The final decision on introduction is made by the person in charge above However, system selection, examination, and proposals are also greatly involved in my position as the group manager (currently the section manager). I receive consultations from employees who are on good terms with the company, and I explain OneCNC at meetings, but in the end, it is not my ability, but rather the balance of each department that determines the outcome.

Like a processing machine, it is considered an expense, and I think OneCNC's ability to keep costs down was a big appeal of OneCNC.In addition to cost, OneCNC is very easy to operate, making it easy for beginners to use. However, it can be learned in a short period of time. I think it was also attractive from the perspective of other departments that new employees and employees who were transferred can immediately become effective.”(*)What is Amoeba.

Ameba Management, is a management method that subdivides a company organization into small groups (ameba) and operates each small group on a self-supporting basis.

It was created by the late Kazuo Inamori, the founder of Kyocera Corporation.

Kyocera Corporation, we asked for an interview because OneCNC is used as the main CAD/CAM in many departments in the same factory.

When I listened to the story, the background was the idea of amoeba management, in which each department pursues profits on their own responsibility. is being evaluated.

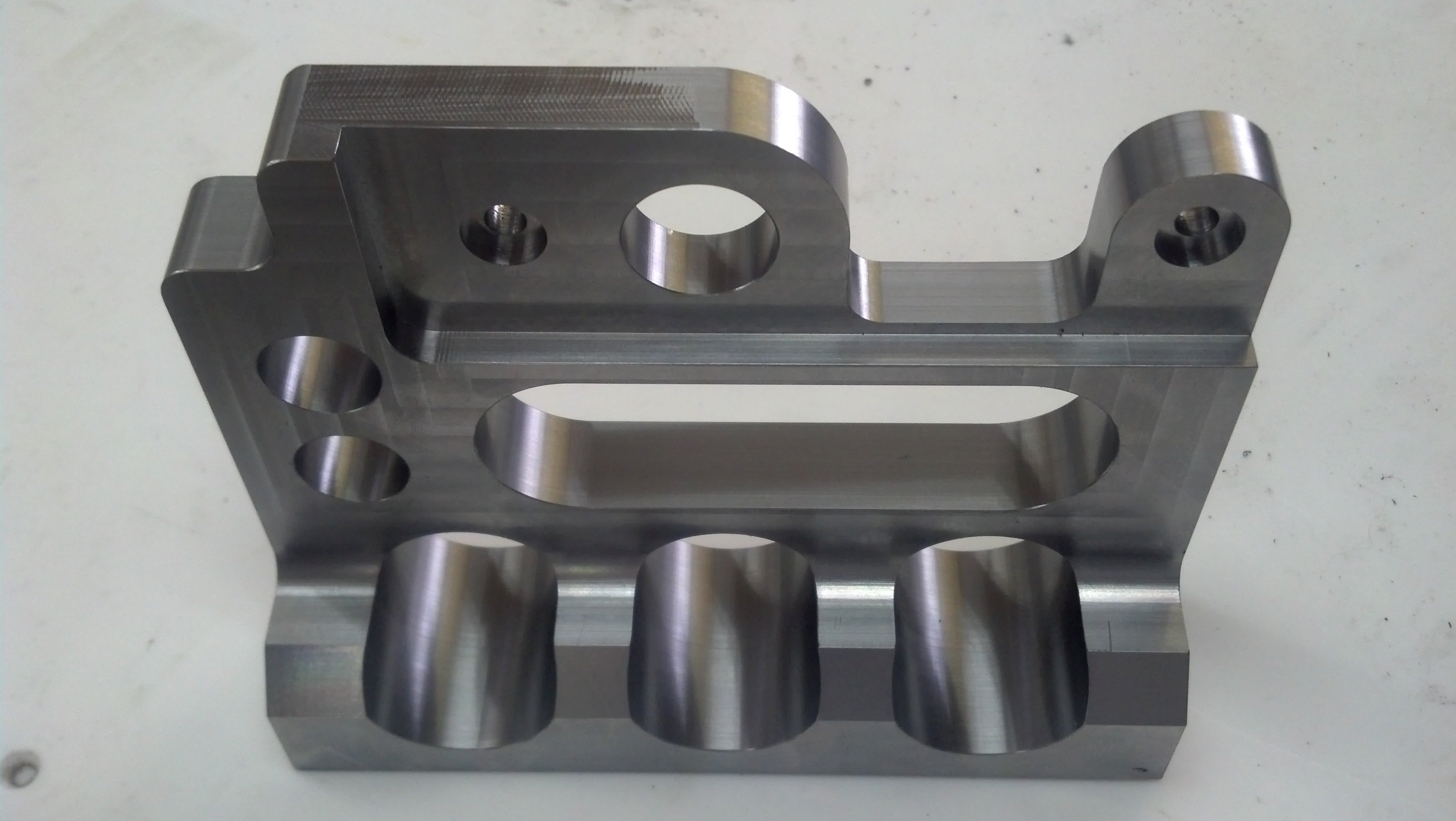

Currently, Mr. Yokoyama is actively working on 5-axis machining using OneCNC's 5-axis option to make full use of the OneCNC function.

I think that Mr. Yokoyama's efforts will not be limited to the same department, but will spread to other departments, and will become an asset for the entire company.

We would like to do our best to help our company in the future.

Mr. Yokoyama, thank you for your cooperation.

▼ User profile

■ Company name: Kyocera Corporation Shiga Yokaichi Plant

■ Location: Jazozocho, Higashiomi City, Shiga Prefecture

■ URL:https://www.kyocera.co.jp/

[Installed products]

OneCNC Mill 3D Expert (Introduced in November 2022)

OneCNC Mill 3D Expert (Introduced in August 2016)

OneCNC Mill 3D Expert (Introduced in October 2013)

OneCNC 5-axis option set (fixed + simultaneous) (2013) (Introduced in October)

OneCNC Mill 2D Express (Introduced in May 2013)

OneCNC 5-axis option set (fixed + simultaneous) (Introduced in July 2010)

OneCNC Mill 3D Expert (Introduced in November 2007)

OneCNC更新

OneCNC XR9 版本 74.53

十一月 23 2023

OneCNC XR9 版本 74.44

九月 25 2023

OneCNC XR9 版本 74.30

七月 06 2023